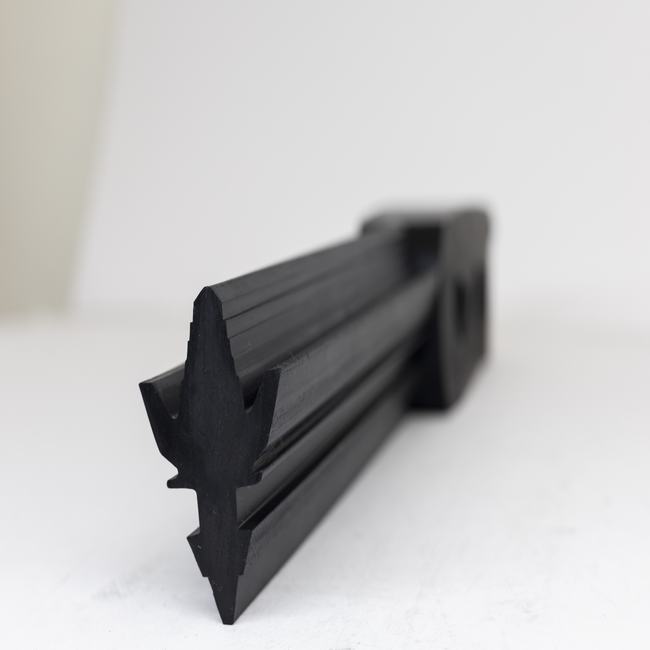

grp pipe seals

GRP (Glass Reinforced Plastic) Grp pipe seals, also known as fiberglass pipe seals or fibreglass reinforced plastic pipe seals, are specialized sealing components used in the installation of GRP pipes or fiberglass-reinforced plastic pipes. These seals are designed to provide a secure and watertight seal at joints, connections, or penetrations in GRP pipe systems. GRP pipes are commonly used in various industries, including wastewater treatment, industrial processes, and infrastructure projects.

Here are some key aspects and uses of GRP pipe seals:

**1. Sealing Function:** GRP pipe seals are primarily used to create a reliable and leak-free seal at joints, connections, or penetrations in GRP pipe systems. These seals prevent the escape of fluids (liquids or gases) and the intrusion of external elements, such as water, soil, or contaminants.

**2. Material Composition:** GRP pipe seals are typically made from materials compatible with the GRP pipes themselves. This may include fiberglass-reinforced composite materials or elastomers designed to resist the corrosive effects of chemicals and environmental conditions.

**3. Types of GRP Pipe Seals:**

- **Coupling Gaskets:** Coupling gaskets are used to seal the joints between two sections of GRP pipes, ensuring a watertight and secure connection.

- **End Cap Seals:** End cap seals are used to seal the ends of GRP pipes, preventing the entry of water, soil, or contaminants into the pipe.

- **Penetration Seals:** In applications where GRP pipes pass through walls or structures, penetration seals are used to create a waterproof and secure seal around the pipe penetration.

**4. Chemical Resistance:** GRP pipe seals are designed to resist a wide range of chemicals, acids, and alkalis, making them suitable for use in industrial processes, wastewater treatment, and chemical plants.

**5. Corrosion Resistance:** GRP pipes and their associated seals are highly corrosion-resistant, making them ideal for applications where traditional metal pipes may corrode over time.

**6. Longevity:** Properly installed GRP pipe seals have a long service life and can withstand the mechanical stress and environmental conditions typically encountered in the industries where GRP pipes are used.

**7. Application Areas:** Common application areas for GRP pipe seals include wastewater treatment plants, chemical processing facilities, desalination plants, industrial manufacturing, and infrastructure projects such as bridges and tunnels.

**8. Installation:** Installation of GRP pipe seals requires careful attention to ensure a proper fit and seal. Sealants, adhesives, or mechanical fasteners may be used to secure the seals in place.

GRP pipe systems have gained popularity due to their durability, lightweight nature, and resistance to corrosion. GRP pipe seals play a critical role in maintaining the integrity and functionality of these pipe systems by preventing leaks and ensuring a secure connection at joints and penetrations. Proper selection and installation of GRP pipe seals are essential to the reliability and long-term performance of GRP pipe systems in various industrial and infrastructure applications.

Yorumlar

Yorum Gönder